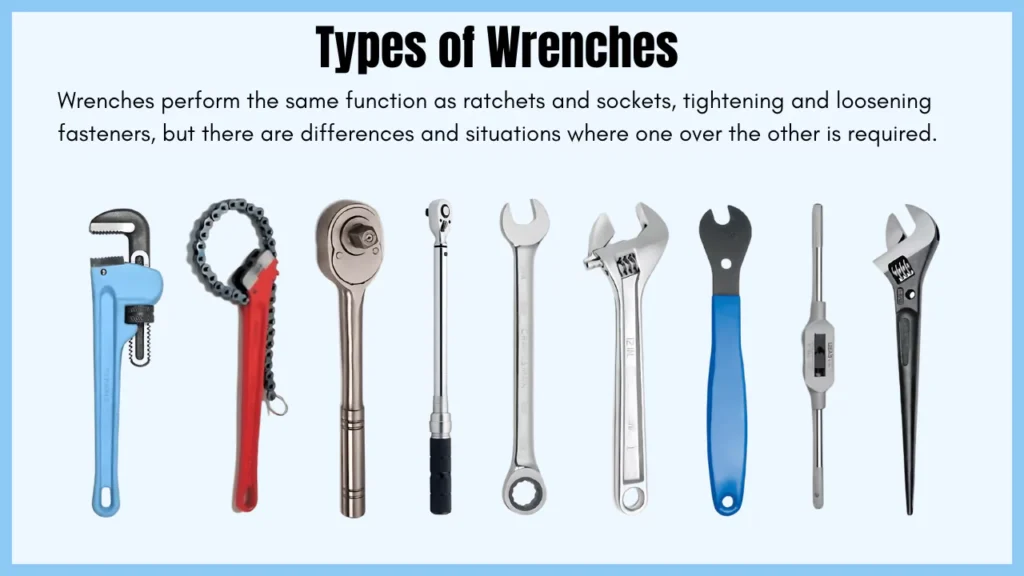

The Complete Guide to All Types of Wrenches: A Tool for Every Job

Wrenches are among the most essential hand tools found in any toolbox, be it a professional mechanic’s workshop or a DIY enthusiast’s garage. Their primary function is to tighten or loosen nuts, bolts, and other types of fasteners. However, there isn’t just one type of wrench; various designs serve specific tasks and applications. In this guide, we’ll take an in-depth look at the different types of wrenches, their uses, and why they’re indispensable.

1. Adjustable Wrench (Crescent Wrench)

One of the most versatile tools in any toolbox, the adjustable wrench is a must-have for both professionals and amateurs. The key feature of an adjustable wrench is its movable jaw, which allows it to accommodate fasteners of varying sizes. This adjustability makes it a convenient tool, especially when dealing with different sizes of bolts or nuts within the same job.

– Best For: Household repairs, plumbing, and general automotive tasks.

– Pros: Adjustable, versatile, replaces multiple fixed-size wrenches.

– Cons: Not as strong as fixed-size wrenches; can slip if not tightened properly.

2. Open-End Wrench

An open-end wrench features two U-shaped jaws that are designed to grip nuts or bolt heads from two sides. These wrenches come in various sizes, typically in sets, and are excellent for working in tight spaces where a box wrench might not fit.

– Best For: Working in confined spaces, quick turns.

– Pros: Faster than adjustable wrenches, great for tight spots.

– Cons: Provides less surface contact, which can round off fasteners if too much torque is applied.

3. Box-End Wrench

A box-end wrench, also known as a ring spanner, is the opposite of an open-end wrench. Instead of an open jaw, it has a closed loop, typically with a six or twelve-point interior, designed to surround the head of a bolt or nut. This feature provides more contact points for a better grip, which makes it excellent for heavy-duty applications.

– Best For: High-torque applications where a firm grip is required.

– Pros: Less likely to slip off the fastener, stronger grip.

– Cons: Limited to specific sizes, not as fast as open-end wrenches.

4. Combination Wrench

A combination wrench offers the best of both worlds, featuring an open-end on one side and a box-end on the other. This dual functionality makes it a popular tool for various applications. You can quickly loosen a fastener with the open end, then flip the wrench over to use the box-end for applying higher torque.

– Best For: General use, automotive repair, and assembly.

– Pros: Versatile, combines the strengths of both open-end and box-end wrenches.

– Cons: Size-specific, requiring a full set to cover different fastener sizes.

5. Socket Wrench

A socket wrench, often called a ratchet wrench, is a tool that uses detachable sockets to accommodate various fastener sizes. The ratchet mechanism allows the user to turn fasteners in one direction without removing the wrench from the bolt or nut, which makes it incredibly efficient.

– Best For: Automotive work, mechanical repair, and tasks requiring speed.

– Pros: Allows for quick fastening and loosening, interchangeable sockets fit many sizes.

– Cons: Bulky, requires multiple sockets.

6. Torque Wrench

A torque wrench is a precision tool used to apply a specific amount of torque to a fastener. It’s a crucial tool in industries where over-tightening or under-tightening can lead to damage or failure, such as in automotive and aerospace applications.

– Best For: Critical applications, like tightening cylinder head bolts or lug nuts to a specific torque specification.

– Pros: Prevents over-tightening, ensures proper torque.

– Cons: More expensive than standard wrenches, requires calibration.

7. Pipe Wrench

A pipe wrench, sometimes called a monkey wrench, is a heavy-duty tool used primarily for turning pipes and other rounded objects. Its serrated jaws provide a strong grip on cylindrical surfaces, making it ideal for plumbing jobs.

– Best For: Plumbing, pipefitting, and general industrial use.

– Pros: Strong grip on rounded surfaces, durable.

– Cons: Bulky, can damage surfaces if used on softer materials like plastic.

8. Allen Wrench (Hex Key)

An Allen wrench, also known as a hex key, is a small L-shaped tool used to turn screws and bolts that have hexagonal sockets in their heads. These wrenches are available in various sizes and are commonly used in furniture assembly and bicycle maintenance.

– Best For: Assembling furniture, adjusting bikes, and working with appliances.

– Pros: Compact, fits into small spaces, simple design.

– Cons: Limited to specific fasteners, can be difficult to apply high torque.

9. Basin Wrench

A basin wrench is a specialized tool used in plumbing, specifically for tightening or loosening the nuts that secure faucets to sinks. Its long handle and swiveling jaw make it ideal for reaching confined spaces under sinks.

– Best For: Plumbing, especially faucet installation and repair.

– Pros: Perfect for tight spaces, designed for plumbing applications.

– Cons: Limited use outside of plumbing.

10. Spanner Wrench

A spanner wrench is a specialized tool designed to work with fasteners that don’t have a standard hex or square head, like circular nuts with notches. Spanner wrenches are commonly used in industries where non-standard fasteners are employed, such as heavy machinery and equipment repair.

– Best For: Specialized industrial applications.

– Pros: Essential for non-standard fasteners.

– Cons: Limited application outside of specific industries.

11. Lug Wrench

A lug wrench, also known as a tire iron, is specifically designed to remove and tighten lug nuts on car wheels. It typically has a cross or L-shaped design and is a staple tool for anyone who owns a vehicle.

– Best For: Automotive tire changes.

– Pros: Simple and effective, necessary for car maintenance.

– Cons: Limited to lug nuts, can be difficult to use without leverage.

12. Crowfoot Wrench

A crowfoot wrench is essentially an open-end wrench head that is used with a ratchet handle. This design allows for access to fasteners in hard-to-reach places, particularly in automotive and industrial machinery repair.

– Best For: Reaching fasteners in confined spaces.

– Pros: Excellent for hard-to-reach spots, works with a ratchet for added torque.

– Cons: Requires a separate ratchet handle, less surface contact than box wrenches.

Choosing the Right Wrench for the Job

When selecting the right wrench for a task, it’s crucial to consider the type of fastener, the amount of torque required, and the workspace. Here are a few considerations:

– Fastener Type: Hexagonal, square, and circular fasteners each require specific wrenches. An Allen wrench, for example, is needed for hexagonal socket screws, while a spanner wrench works for round nuts with notches.

– Space Constraints: If you’re working in a tight spot, an open-end or crowfoot wrench may be better suited than a socket wrench, which can be bulky.

– Torque Requirements: For applications where specific torque settings are critical, such as automotive or industrial assembly, a torque wrench is the best choice.

– Durability and Material: Wrenches come in different materials, including chrome-vanadium steel and stainless steel. For heavy-duty jobs, opt for high-quality materials to ensure longevity and performance.

Conclusion

Wrenches are indispensable tools that come in a wide variety of types, each suited to different tasks. Whether you’re tightening a bolt in a home repair job, assembling furniture, or working on a car engine, there’s a wrench designed specifically for the task at hand. Understanding the differences between these tools will ensure you always have the right one for the job, making your work easier, faster, and more effective.

Having a well-rounded set of wrenches in your toolbox is a long-term investment that will serve you well in countless situations, from DIY projects to professional repairs. Whether you need an adjustable wrench for versatility, a box-end wrench for torque, or a specialized tool like a basin wrench for plumbing, there’s a wrench for every application.

Hello.

Good cheer to all on this beautiful day!!!!!

Good luck 🙂